- +92-321-3500003

- info@asianpolymer.com

- 34 KM Khori Stop Main GT Road Muridke

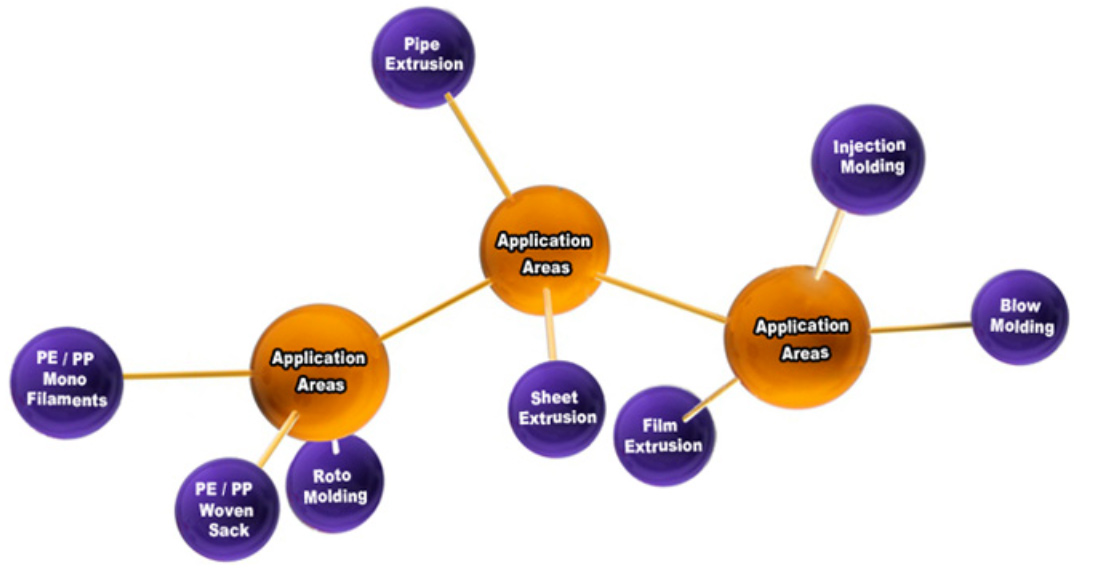

Calcium Carbonate Filler Masterbatch we offer is the most effective cost-saving solution for worldwide plas-tic processors.

CaCo3 Filler Masterbatch not only cuts down plastic production costs by replacing a part of virgin polymer during extrusion, injection and blow molding, but also increases output, improves production conditions as well as a number of physical and chemical properties of finished plastic products.

With a variaty of choices in the market CaCo3 Filler Masterbatch may remarkably differ in quality due to different formulations(CaCO3 content, carrier polymers type & content, chemical additives), compounding technologies as well as technical team skills they were made with/by, even in the same country or geo-graphical area.

A number of factors must be considered to evaluate overall CaCO3 filler quality. Average particle size, top-cuts and calcium carbonate content are the most important ones to influence filler price.

PE calcium carbonate masterbatch: used for PE film, PE sheet, PE pipe, PE bottle.

PP calcium carbonate masterbatch: used for PP sheet, PP pipe, PP yarn, PP injection mould.

PS calcium carbonate masterbatch: used for PS sheet.

Transparent filler masterbatch: used for clear LDPE/LLDPE/HDPE film, clear PE/PP sheet, pipe, bottle

API-PE80 is a highly filled calcium carbonate filler masterbatch containing fine pure CaCO3 in polyethylene resin and special additives.

This CaCO3 filler masterbatch is intended to be added into polyolefin compatible resins during extrusion, injection or blow molding to displace a portion of the resin, thus cutting down the costs while improving product properties.

Adding ratio may typically range from 20% to as high as up to 60% depending on the particular product and processing conditions.

PE Blow Molded Items, PE Films & Bags

HFPE garbage bags, HDPE shopping bags

PE agricultural films, PE biodegradable bags

PE breathable films, PE rolled bags

PR T-shirt bags, PE injection molded items

Basic specification

|

Property |

Test Method |

Unit |

Result |

|

PE & Additive |

|

% |

20 ± 1 |

|

Shape |

Granule |

mm |

2-3mm |

|

Density |

ASTM D1505 |

g/cm3 |

1,60g/1cm3 |

|

Moisture |

ASTM D644 |

% |

<0,2%

|

|

CaCO3 Percentage |

|

% |

80 ± 1 |

|

CaCo3 Particle Size (D50) |

Malvern Mastersizer 3000E |

µ |

2.5 ± 0.3 |

API-PE82 is a highly filled calcium carbonate filler masterbatchcontaining fine pure CaCO3 in polyethyl-ene resin and special additives.

This CaCO3 filler masterbatch is intended to be added into polyolefin compatible resins during extrusion, injection or blow molding to displace a portion of the resin, thus cutting down the costs while improving product properties.

Adding ratio may typically range from 20% to as high as up to 60% depending on the particular product and processing conditions.

PE Blow Molded Items, PE Films & Bags

HFPE garbage bags, HDPE shopping bags

PE agricultural films, PE biodegradable bags

PE breathable films, PE rolled bags

PR T-shirt bags, PE injection molded items

Basic specification

|

Property |

Test Method |

Unit |

Result |

|

PE & Additive |

|

% |

18 ± 1 |

|

Shape |

Granule |

mm |

2-3mm |

|

Density |

ASTM D1505 |

g/cm3 |

1,60g/1cm3 |

|

Moisture |

ASTM D644 |

% |

<0,2%

|

|

CaCO3 Percentage |

|

% |

82 ± 1 |

|

CaCo3 Particle Size (D50) |

Malvern Mastersizer 3000E |

µ |

2.5 ± 0.3 |

© 2023 Asian Polymer Industries. All Rights Reserved | Design by WebOjoSoft